We are deep-hole drilling specialists!

Difficult material? Offset hole? Bore circles? No problem.

If it fits on our machines we have the know-how to drill almost anything. Whether you need a complete part or just a hole to get you started. We can get it done in spec and on time. We can also bore existing holes in tube and finish to your tolerance and finishing requirement. See below to learn about the drilling process and our common sizes.

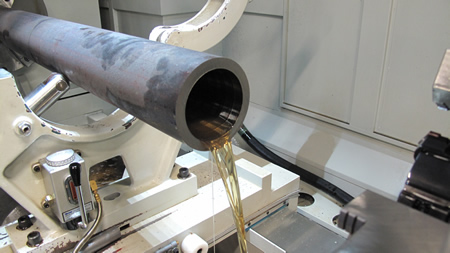

Deep hole drilling (BTA or STS drilling, also known as Gun Drilling )  was developed for drilling deep holes in steel in gun barrels, hence it is also known as Gun drilling. Armament manufacturing continues to be a common use of this process. Other common industries include energy, oil and gas exploration, engines, diesel fuel components, and plastic injection moulds. This process produces deep, straight holes in a variety of materials. A gun drill tool differs from a conventional twist drill by its unique head geometry. In this process of deep hole boring a fluid is pumped to the work-piece while the cutting head advances in the material. The high volume of fluid pushes the cuttings through the center of the tube and discharges out to a conveyor.

was developed for drilling deep holes in steel in gun barrels, hence it is also known as Gun drilling. Armament manufacturing continues to be a common use of this process. Other common industries include energy, oil and gas exploration, engines, diesel fuel components, and plastic injection moulds. This process produces deep, straight holes in a variety of materials. A gun drill tool differs from a conventional twist drill by its unique head geometry. In this process of deep hole boring a fluid is pumped to the work-piece while the cutting head advances in the material. The high volume of fluid pushes the cuttings through the center of the tube and discharges out to a conveyor.

Originally a time-consuming and costly process, today’s technological advances make Deep hole gun drilling a highly efficient manufacturing operation in all metal cutting industries. With a standard twist drill it is difficult to maintain precision when the depth to diameter ration is very high. Gun drilling is an ideal solution for most deep and precision drilling projects. This high precision operation produces accurate, repeatable holes, with excellent surface finishes. Gun drills hold location to precise tolerances, are sized to exact specifications, produce burr free holes, and can be formed to produce specific shapes in blind holes with minimal machine adaptation. This process works extremely well in difficult to machine materials such as stainless steels, duplex alloys and heat-resistant super alloys. Holes deeper than 20:1 generally require a dedicated gun drilling machine to achieve highest productivity and process reliability.

Gun Drilling

Quality Gun Drilling differs from the BTA/STS type of gun drilling due to the coolant entry and chip removal. Gun drills introduce coolant through a small hole within the tool, and chip removal occurs through a groove outside the tool. BTA drilling has fluid enter through a mechanism around the tool, while chips are evacuated through the drill itself.

With our specialized knowledge, we have been able to help customers design plausible and cost-effective solutions. Using the latest equipment available, we can handle an unusually large percentage of all gun drilling jobs. We can manufacture multiple hole types such as blind, stepped and thru holes to name just a few. MIR is capable of machining continuous holes from 20mm to 80mm (0.787 to 3.150 inch) diameter in solid materials up to 2 meters deep (80 inches). We are also capable of boring existing holes to sizes up to 150mm (6 inches).

Common Deep Hole Drill Head Size’s – contact us for other sizes! |

|

| MM | Inch |

| 31.75 | 1.250 |

| 34.93 | 1.375 |

| 36.00 | 1.417 |

| 38.10 | 1.500 |

| 39.00 | 1.535 |

| 41.30 | 1.625 |

| 43.00 | 1.693 |

| 44.45 | 1.750 |

| 45.20 | 1.780 |

| 47.00 | 1.850 |

| 47.60 | 1.875 |

| 49.28 | 1.940 |

| 50.70 | 1.996 |

| 50.80 | 2.000 |

| 53.00 | 2.087 |

| 54.00 | 2.126 |

| 57.90 | 2.280 |

| 60.30 | 2.374 |

| 62.00 | 2.441 |

| 63.50 | 2.500 |

| 67.30 | 2.650 |

| 69.80 | 2.748 |

| 76.10 | 2.996 |

| 79.90 | 3.146 |

| 80.00 | 3.150 |